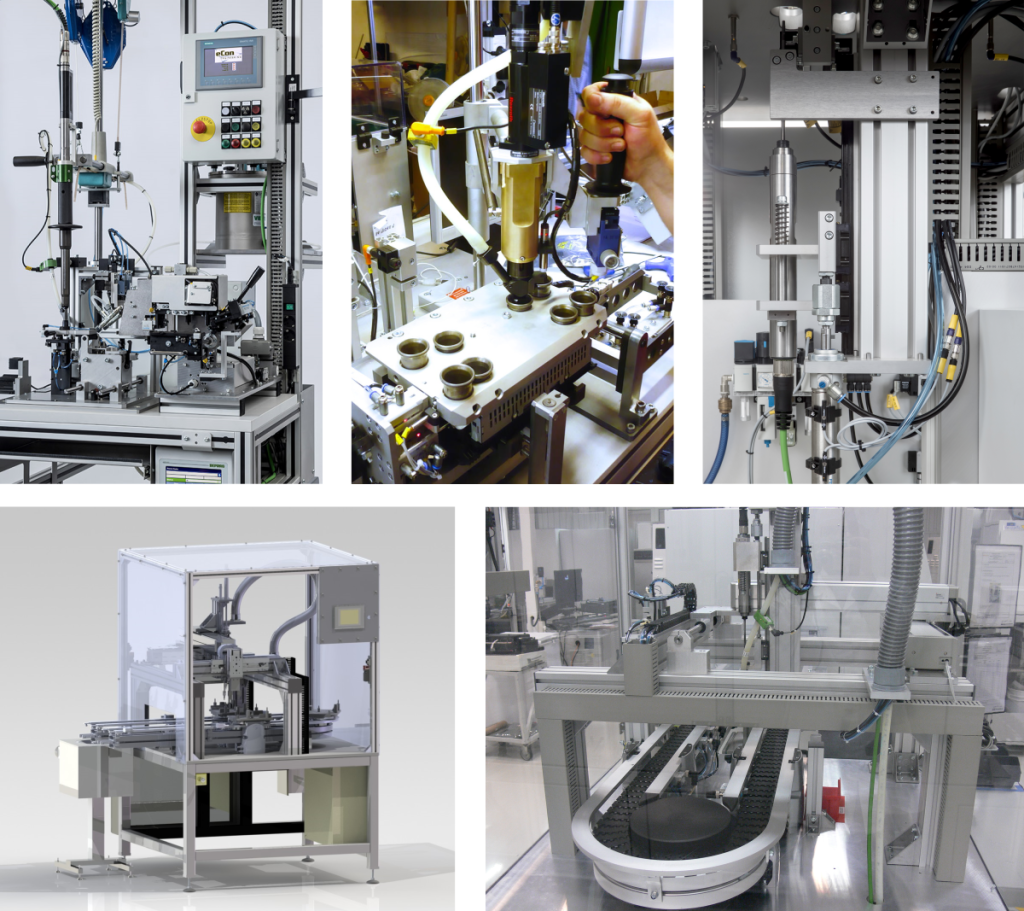

Our assembly machines are based on the integration of many, modular constructed components. According to the required assembly step, we will determine the best possible solution and we will integrate it into your line – regardless if it’s a fully robotic or a manual workstation. The assembly line may consist of speed-optimized machines with indexing table, highly-flexible conveyor systems or some totally customized units; this will be all up to your priorities.

Whether the task is screw-driving, pressing, press-fitting, plasma treatment, welding, stamping, testing, camera inspection, leak testing, handling, riveting, labelling, cutting, gluing or any other assembly installation you need we can offer many flexible solutions. Our aim is to reach the highest process reliability and functional safety possible.

Screwing equipment

At eCon Engineering we are able to cover the full spectrum of screw-driving technologies. According to the required technologies, we will try to find the best solution and integrate it into your line – regardless if it’s a fully robotic – or a manual workstation.

The system may be a speed-optimized machine with indexing table, a highly-flexible conveyor system or a totally customized manual unit; this will be all up to your priorities. Our design specialist experiences will be applied to your screw-driving station decreasing the cycle time while increasing the reliability.

Test equipments

Quality is now the deciding factor for the success of a product. In line inspection, measuring and testing, elevates the product quality to a continued high level of standard. At eCon Engineering we are able to cover a wide spectrum of inspection and test technologies.

Whether you need to measure the force-displacement of a press-fit process, the torque of a screw-tightening process, the possible leakage, some electrical parameters, or simply just want to verify the positioning or a dimension of your part with a camera, we can integrate the necessary solutions directly and usefully into your machine, or deliver an EOL tester for your product.