The new ANSYS 2020 R1 offers even more efficient solutions! Below you find a summary of the most important changes. However, despite our best efforts, it is impossible to fit all highlights into such an article. Should you need more information, do not hesitate to write us at sales@econengineering.com! We’ll be happy to answer any questions you may have!

What’s new in ANSYS Mechanical (highlight)

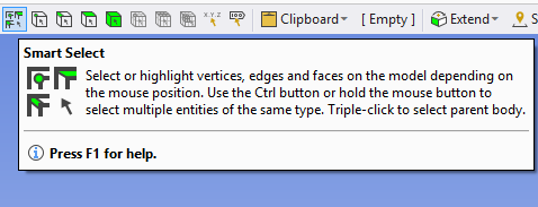

Smart Select

The popular tool of SpaceClaim arrived to Mechanical. Vertices, edges and faces can be selected depending on the mouse position. There is no need to change selection type if we would like to rather select and edge instead of a face.

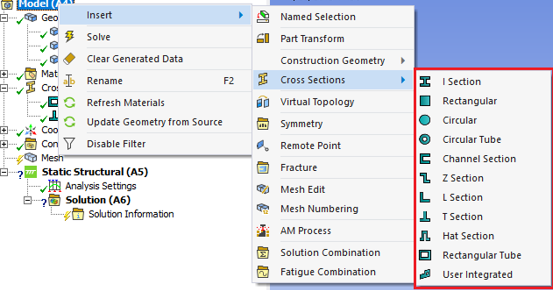

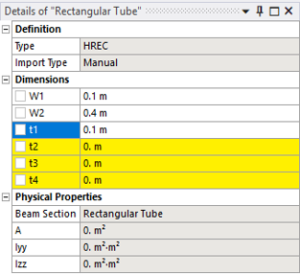

- Editable cross section

The Cross Section definition does not require SpaceClaim (or DesignModeler) anymore! It speeds up working with beams, cables, links, since there is no need to go back to SpaceClaim (if its license is available for the user at all) to adjust the geometry. A Profile view became available in the menu to investigate our cross sections.

- Changes in Scipting

The ACP user interface is now based on Python 3.7.4 and many third-party software packages have also been updated. Do not forget to check your scripts compatibility with Python 3 before running it in 2020 R1! The ACT Console has been replaced with a new scripting window. It gives us the possibility to build up and execute our full script in the Mechanical GUI. In the meantime it also provides access to a Shell window, where we can try the different commands (as in case of the former ACT Console) and investigate the execution of the script. For those who prefer the Console it can be restored in the UI Options of the Mechanical Options. A new features also has been added to API. Now it is possible to import mesh directly into Mechanical and the already evaluated results can be plotted into the Shell.

Distributed Compute Services

ANSYS introduces a host of new services that enable the distributed evaluation and management of simulation workflows: They are called DCS, the Distributed Compute Services. As a part of this, Design Point Service (DPS) allows the robust and distributed evaluation of tens of thousands of Design Points, starting from a standard ANSYS Workbench simulation project.

- Additive Manufacturing

Several new features and update appears for Additive Manufacturing in 2020R1 release. The pre-processing tool for additive manufacturing, the SpaceClaim built-in Additive Prep now can create Tree supports, write build files and set printing parameters. With the new Cost Estimator now the cost of the printing can also be estimated.

The ANSYS Additive Print and Science which are created for machine operators and material scientist now provide among others, J2 plasticity, larger build size, and connection to Workbench Additive. The AlSi10Mg material parameters has been validated to every simulation type

In the Workbench Additive now the Inherent Strain Method has become fully supported and SSF calibration has been added. A new macro makes possible to combine Layered Tet meshed part with voxel support, thus complicated geometries can be meshed effectively. The Wizard also has been updated with the new functions.

- Topology optimization

New validation workflow has been introduced for 2020 R1, where the results of a topology optimization can be directly exported into a new Mechanical system for validation via a smoothing. In Static systems Primary and Composite Criteria make possible to create custom expression between different results of our simulation to constrain our optimization.

For the traditional, Density-based topology optimization method Bolt Pretension became available, while for the new Level-set method new manufacturing constraint has been introduced. As a beta feature Node-Based Shape Optimization appears in the ANSYS portfolio.

- Direct Pressure

For 3D solids now direct pressure loading is available on element faces. This solution doesn’t use surface load elements therefore it requires less computational capacity and it can be easily added at restart, since new elements do not have to be created.

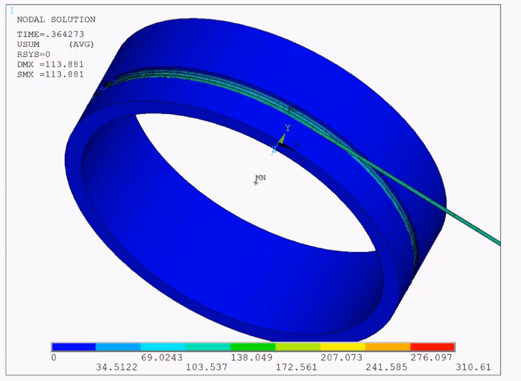

- Cable element

The 3D 3-Node Cable Element CABLE280 is introduced, which is suitable for analysing moderate to extremely slender cable structures. It is computationally efficient with only translational DOFs, and it has Mixed Displacement / Force formulation for superb solution accuracy and robustness.

- New Bolt Pretension

With 2020 R1 a new Bolt Pretension formulation is available, which uses MPC184 element. This new solution provides reliable results, when a bolt undergoing large rotation or large deformation.

- New Interference Fit

A New Interference Fit modelling technique makes possible to activate ramped option during specific load steps or time period. The method ramps the normal and tangential contact stiffness, friction coefficient, and it requires no initial engagement.

What’s new in ANSYS Fluids (highlight)

Fluent

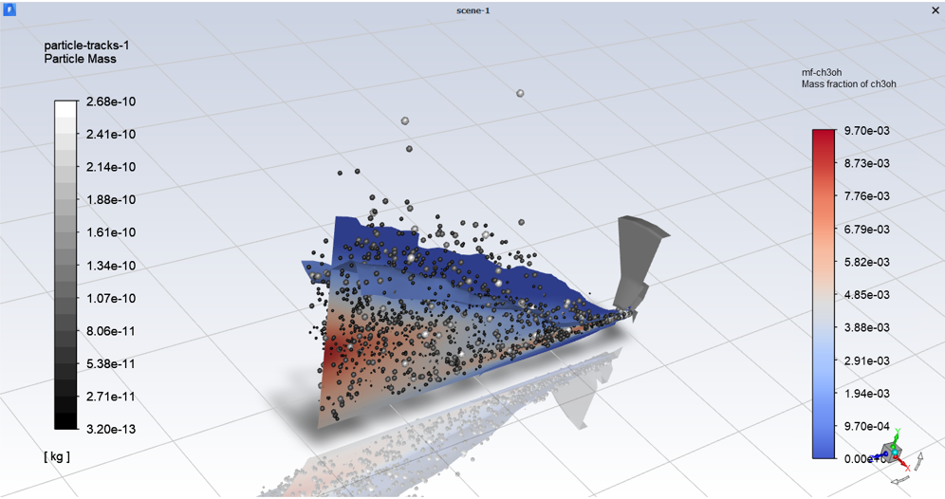

New graphic user interface.

Provides a more spectacular look with the new rendering and reflections options what you can freely modify.

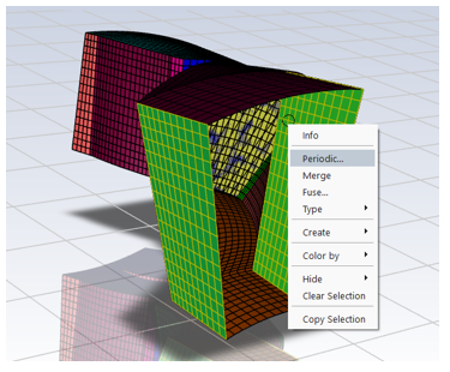

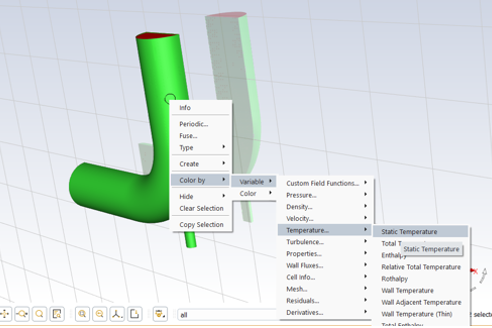

Simpler, faster operation thanks to the new graphical user interface. Only a click on the appropriate surface and select the condition you want to define on it from the pop-up menu, such as surface periodicity in the meshing process or creating color plot during the postprocessing.

- Watertight Geometry:

Many new options have been added to the workflow. Most of these focusing for the local sizing. Also, the boundary layer setup is more detailed. You can now specify different prism layer on surfaces.

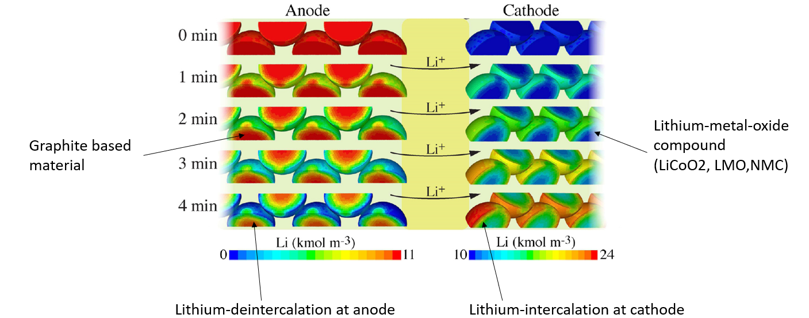

- Full 3D Li-ion electro-chemistry modeling

A fully 3D Li-ion electrochemical model for manufactures and suppliers of battery cells.

The model solves Li + ion transport between the anode and the cathode during charge and discharge.

- Improved data processing speed

Case/Data files will now be written in the *.cas.h5 / *.dat.h5 (CFF) format by default, which allows Case write performance average of ~10x to ~20x faster than before, and read performance ~50% – ~100% improvement.

For data files, the occasional write speed improvement is 30%, for compressed Data it can be up to 5 times better, for reading the speed up is 15% -30%.

CFX

- Harmonic Analysis

Improved convergence, paticularly when solving for many harmonics. Robust convergence allows for larger pseudo-timesteps, dramatically reducing solution times

2 – 3x faster than previous versions.

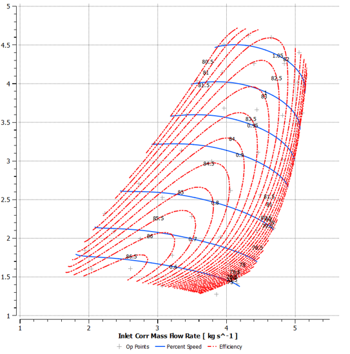

Operating Maps news

- Preferences control for default Solver Manager Workspace layout. Allows a user-specified layout to be loaded automatically when monitoring a new run.

- Response point filtering for contours: filter out operating points from response contour plots based on specified criteria for input and output parameters. E.g. exclude operating points that are below a pressure ratio of 1.

- Response Surface quality metrics. Solver run continuation “Continue All” for operating points after making mesh changes.

- Blade Film Cooling

The injection location can be displayed during a CFX-Pre installation with a color injection location with injection quantities, and vectors can be shown to display the injection direction.

What’s new in ANSYS Electronics Desktop (AEDT) 2020 R1?

ANSYS Maxwell

Element-based volumetric harmonic force coupling – Due to this, the deformation caused by magnetostriction can be fully taken into account in Mechanical/Acoustic simulation. Demagnetization coefficient – A new quantity found in the results of 2D or 3D transient simulations gives quantitative information about the magnetization of the magnet. This new feature is illustrated in Fig. 1./a. The Litz wire modelling is now available in eddy current simulation, not just in transient. New machine types are available in Electric Machine Toolkit (along with permanent magnet synchronous machine and asynchronous machine): synchronous reluctance machine; switched reluctance machine.

Figure 1. – Two illustrations of the new features.

ANSYS HFSS

HFSS SBR+ creeping wave physics is included in the antenna modelling, to take into consideration of antenna proximity to the platform. Near field H (magnetic field strength) and Poynting vector are available as results and Poynting field for 5G power density calculation. Save the field results only a specific object or face list, which saves memory. It is already possible to use circuit elements in predefined (encrypted) 3D components. Template examples and 3D Components for EMI/EMC applications based on different international standards are available in examples library. Fig. 1./b. shows an example about conducted emission analysis.

Additional:

- Not the only steady-state but transient Icepak simulation is possible within AEDT.

- New Convective Heat Transfer Coefficient Toolkit in AEDT Icepak, which determines the heat transfer coefficient based on specified inputs.

- New SpaceClaim CAD Cleanup ACT that simplifies and speeds up engineering work with Icepak. This ACT will execute some cleanup tasks based on user inputs and automatically goes through Icepak simplification processes for each object in the model.

******************************

For more information on ANSYS 2020 R1 do not hesitate to contact us at sales@econengineering.com.

You can download the new ANSYS 2020 R1 Capabilities here.

You can also find additional information about the new release on the ANSYS website.