eCon Engineering uses simulation to design and optimize a new carbon composite structure

ABOUT QUIET

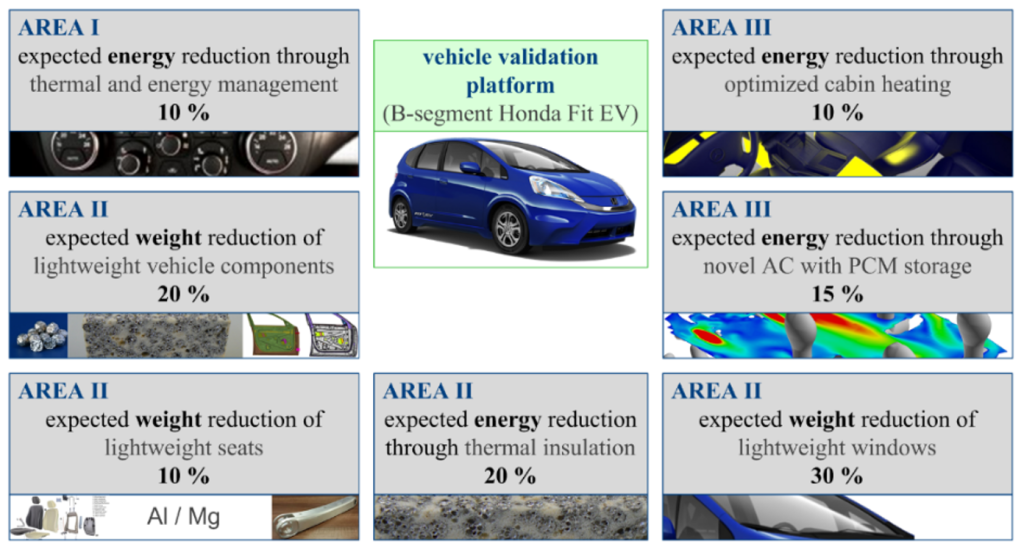

The QUIET project (QUalifying and Implementing a user-centric designed and EfficienT electric vehicle) targets weight reduction and thermal inertia while improving the thermal insulation of an electric vehicle (EV) to improve efficiency without reducing performance. It aims to develop an improved and energy efficient electric vehicle with an increased driving range for real-world driving conditions. This is being achieved by exploiting the synergies of a technology portfolio (see Fig. 1) in the areas of:

- user centric design with enhanced passenger comfort and safety,

- lightweight materials with enhanced thermal insulation properties, and

- optimized vehicle energy management

eCon Engineering, as the work package leader for lightweight materials with enhanced thermal properties, is working with composites and novel hybrid foam materials to reduce the weight of EV closure elements while improving their thermal properties in close cooperation with other members of the consortium e.g. Austrian Institute of Technology and Fraunhofer IFAM.

AIM

The QUIET Work Package 3 (WP3) aimed to develop lightweight glazing, closure elements (e.g. side doors, trunk lid and engine hood) and seats, all with improved thermal properties. The goal was to reduce weight by 30% for glazing, 20% for closure elements, and 10% for the lightweight seat structure, in addition to improving the thermal properties in terms of the demonstrator vehicle’s energy consumption during heating or cooling of the cabin.

METHOD

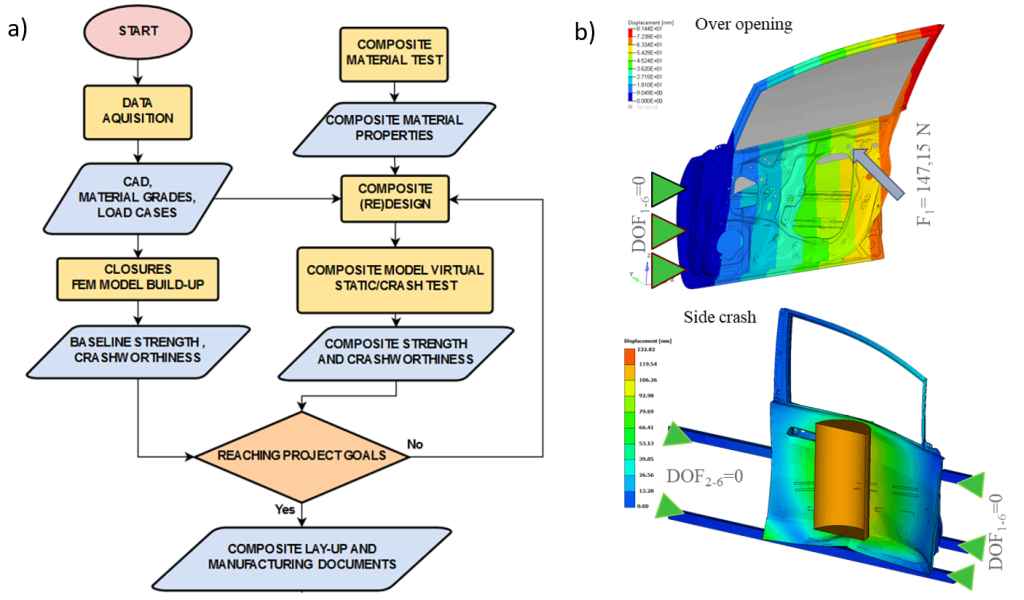

The development process (see Fig. 2a) began with data collection and analysis of the current structure to estimate the potential for mass reduction and for optimization of the thermal properties. From the results for the original structures (which served as the baseline), an extensive research and development process was conducted using material sciences, computer aided design and the finite element method (FEM). In each case, a multi-step iteration process was performed to optimize the newly developed structures and to achieve the best possible result. At the end of the development, the previously set goals for weight reduction as well as the thermal properties were achieved.

For the lightweight closure elements, a carbon composite design was developed and optimized according to a predefined development process, using weight-cost and weight-strength trade-offs. To do this, a design of experiments (DoE) process was used to identify areas where composite redesign could be effective and areas where preserving the original structure would be more useful. In this work phase, simulations were performed using ANSYS Composite PrepPost (ACP) to construct models under static loads, and LS-DYNA to calculate the side collisions (see Fig. 2b).

RESULTS

At the end of the development process, trade-offs between mass, cost, thermal properties, and stiffness were ascertained, and the best possible composite-layer structure for each target component was determined.

Not only were the lightweight structures designed, but they were also manufactured as prototypes (see Fig. 3) to be implemented in each case in the demonstrator vehicle of the QUIET project. Therefore, the result of this work package was not only a new design concept and production plan, but also real parts with significant weight reduction and better thermal insulation or lower heat capacity, which can be implemented and tested in the last phase of the project, in 2020.

In all sub-tasks of WP3, we also calculated the possibilities of economic upscale. They show what the costs of using newly developed solutions would be not only for prototype vehicles but also for higher series vehicles.

Acknowledgement:

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 769826. The content of this publication is the sole responsibility of the Consortium partners listed herein and does not necessarily represent the view of the European Commission or its services.

Author: Tamas Turcsan is Structural Analyst Engineer and Project Manager of QUIET H2020 at eCon Engineering