Author: Tomislav Breški, M. Eng. M. E., Faculty of mechanical engineering and naval architecture, Department for polymer processing, University of Zagreb, Croatia

Keywords: injection moulding; mould inserts; additive manufacturing; thermosetting metallic composite, thermal properties, cooling efficiency; transient cooling analysis

1.) Introduction

Injection moulding is one of the most common production processes for making plastic parts. The process of making injection moulds is time consuming and technologically demanding, so rapid tooling processes are emerging as an alternative to conventional manufacturing processes. The thermosetting parts of the mould produced by additive manufacturing processes have satisfactory geometric characteristics, but due to the nature of polymeric materials they have worse thermal and service properties than the metal mould components. The paper will examine the possibility of application of thermosets-metal mould components in order to extend mould lifespan. At the same time, it will be examined how the composite material affects heat exchange. Polymeric mould inserts are already adopted by industry in small scale production due to their initial low cost, so research in this field has a strong potential to be used on industrial scale. Numerical results have been calculted utilising CoreTech Moldex3D.

2.) Geometry

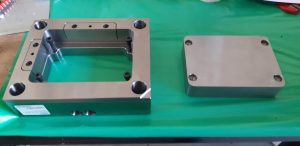

Experimental part of this research is planned to utilise Meusburger Quick change mould system, shown on figure 1, so the simulation model has to include all the parts from mould plates, mould inserts, to cooling channels.

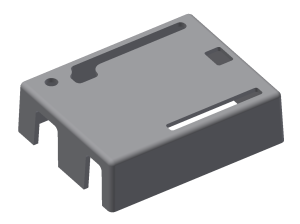

Since this research is funded by Faculty of mechanical engineering and naval architecture, part to be injection moulded is a case for Arduino Uno PCB, which is widely used during classes related to automation and process regulation. Arduino case is shown on figure 2. Only top part of the case is used in this paper, but final production mould will have two cavities, one for top part of the case and one for bottom half of the case.

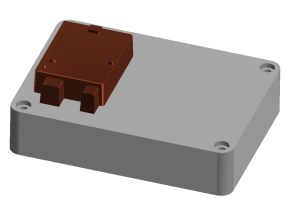

Assembled movable mould plate with thermosetting metallic mould insert is shown on figure 3.

3.) Simulation model

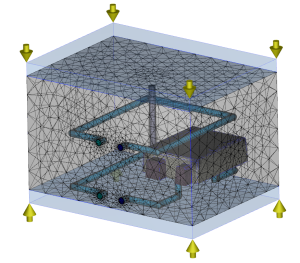

Injection moulding process is simulated using CoreTech Moldex3D software which by utilising numerical finite element based thermo – mechanical calculations is able to simulate many aspects of injection moulding processes. Meshed assembly is shown on figure 4.

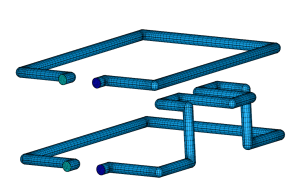

Thermosetting metallic mould inserts are made through reaction moulding using epoxy or polyesther resin as a matrix, cooling channels can be produced using wax 3D printing, which are inserted in still wet resin mixture in the appropriate position of the mould insert mould, and after the resin has set, by heating the mould insert to melt temperature of the wax, cooling channels are exposed and ready for installation in the movable mould plate. Numerical model of cooling channels is shown on figure 5.

4.) Results and discussion

In order to find whether the thermosetting metallic mould inserts are viable option for industrial application, all phases of injection moulding process need to be simulated, so the appropriate analysis sequence in CoreTech Moldex3D is as follows:

- Steady state mould preheat (C)

- Fill (F)

- Pack (P)

- Transient mould tempering (Ct)

- Warp (W)

Two mould insert materials are taken into consideration. In first case, selected mould material is 1.2312, and in the second case, polyesther resin filled with copper particles. UNP – copper material properties are defined according to Yahan, 2019 [1]

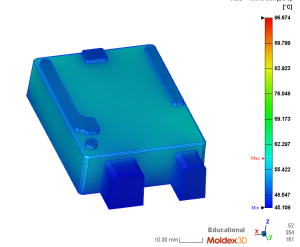

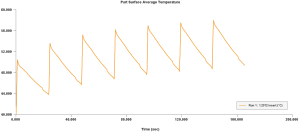

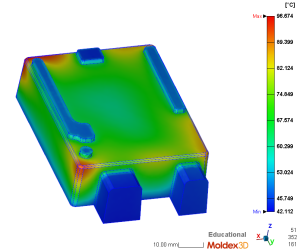

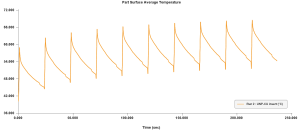

On figures 6 and 8 final temeperature distributions of mould inserts are visible. Temperature scales are set to identical values, so both cases can be compared. As expected, composite mould insert has much lower thermal properties, so temperature distribution is quite bad, especially in tight areas and corners of mould insert. Maximum temperature of composite mould insert is around 96 °C, which is higher compared to 1.2312 insert, but by increasing the cooling time and by optimizing the shape and position of conformal cooling channels, temperature peaks can potentially be avoided, which is still yet to be investigated. Transient cooling analysis has shown that the 1.2312 insert converges faster to consistent mould temperature, which originates from less injection moulding cycles shown on figures 7 and 9. Since the emphasis in this paper is not in shortening the cycle time, slower thermal reactions of UNP-Cu mould inserts are not necessarily a con. Also, if we investigate close to instantaneous temperature jump in first contact of polymer melt with mould surface, it can be seen that in the case of UNP-Cu mould insert, temperature jump is higher, so it is possible to set-up the injection moulding process with lower initial melt temperature.

5.) Conclusion

As shown in this paper, applicability of thermosetting metallic mould inserts was investigated. According to achieved results, composite mould inserts are more susceptible to heat accumulation, and as such, injection moulding cycles need to be extended, compared to standard mould materials. Nevertheless, in small scale production cases, cycle times are not a relevant factor, so initial lower price of composite mould insert is a big advantage. Additional reseach in this is yet to be done, but application of thermosetting metallic mould inserts is a very interesting and novel approach in injection moulding, and has a great potential to improve small scale companies who have small budgets for production

Acknowledgments

I would like to express my very great appreciation to eCon Engineering Kft., who provided me with a research licence for Moldex3D in which this preliminary research has been done.

Literature

[1] – S. A. Jahan and H. El-Mounayri, “A Thermomechanical Analysis of Conformal Cooling Channels in 3D Printed Plastic Injection Molds,” Appl. Sci., 2018.